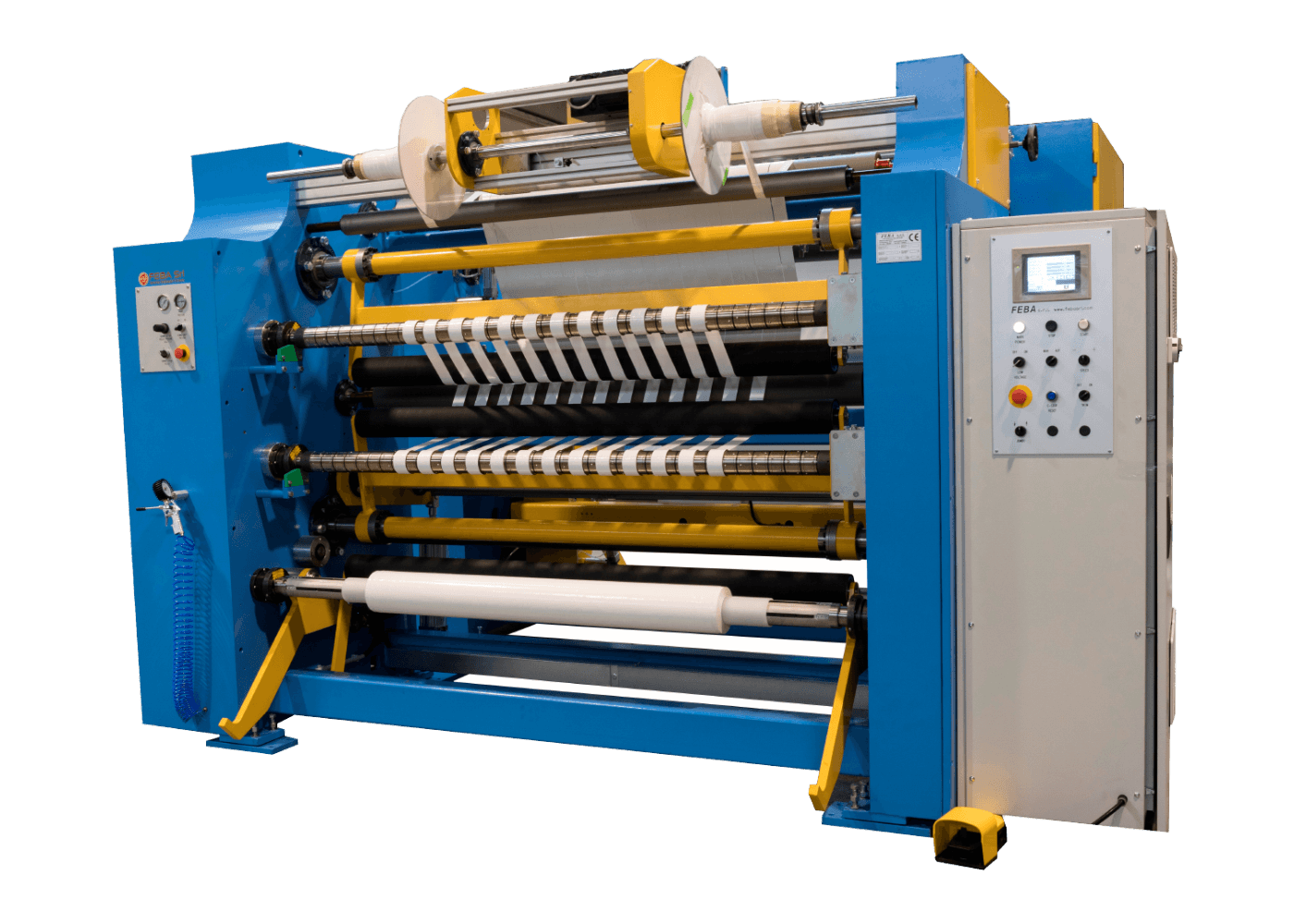

FEBA

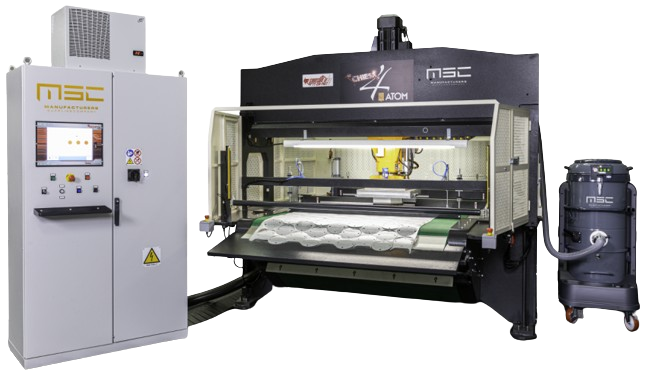

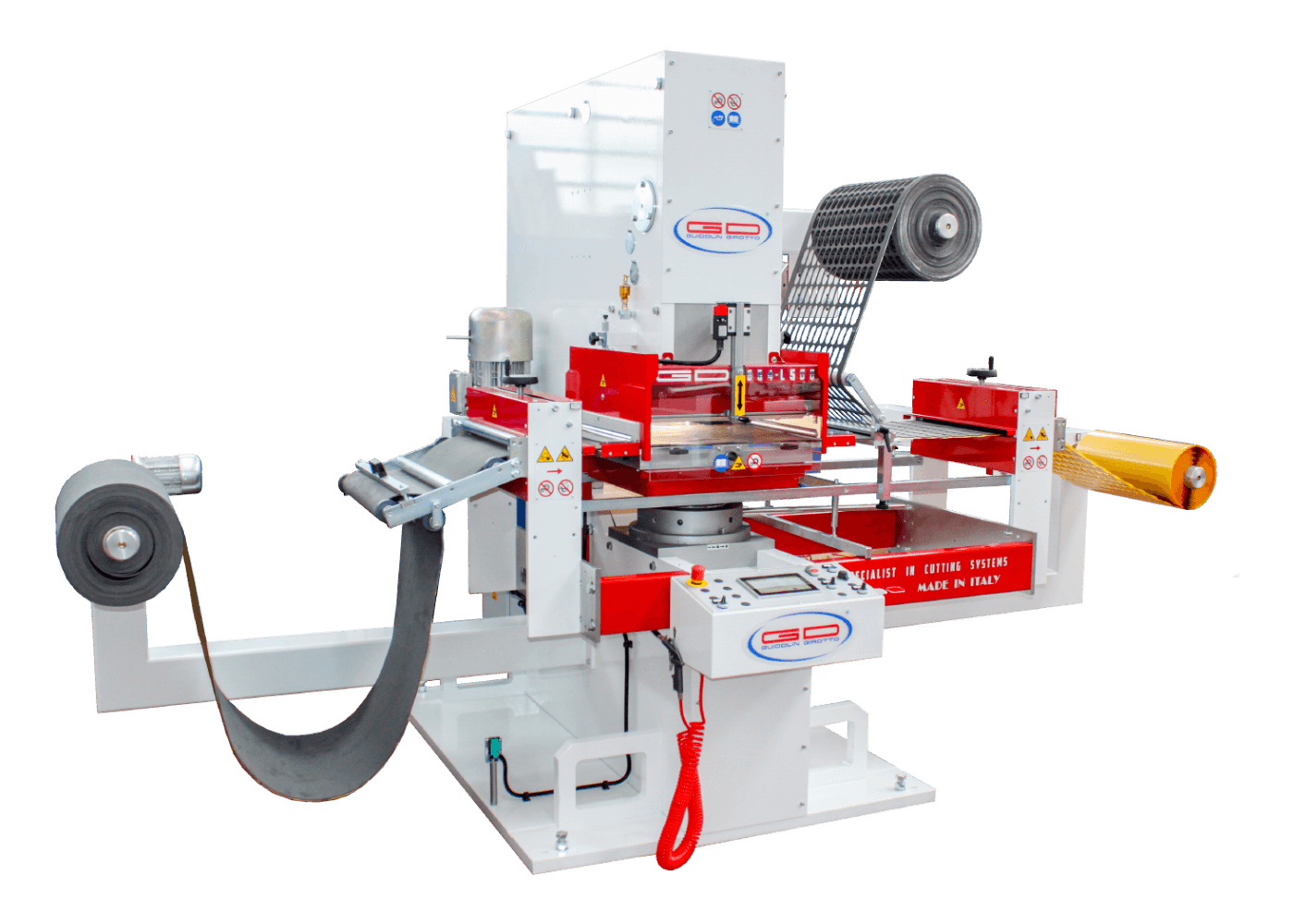

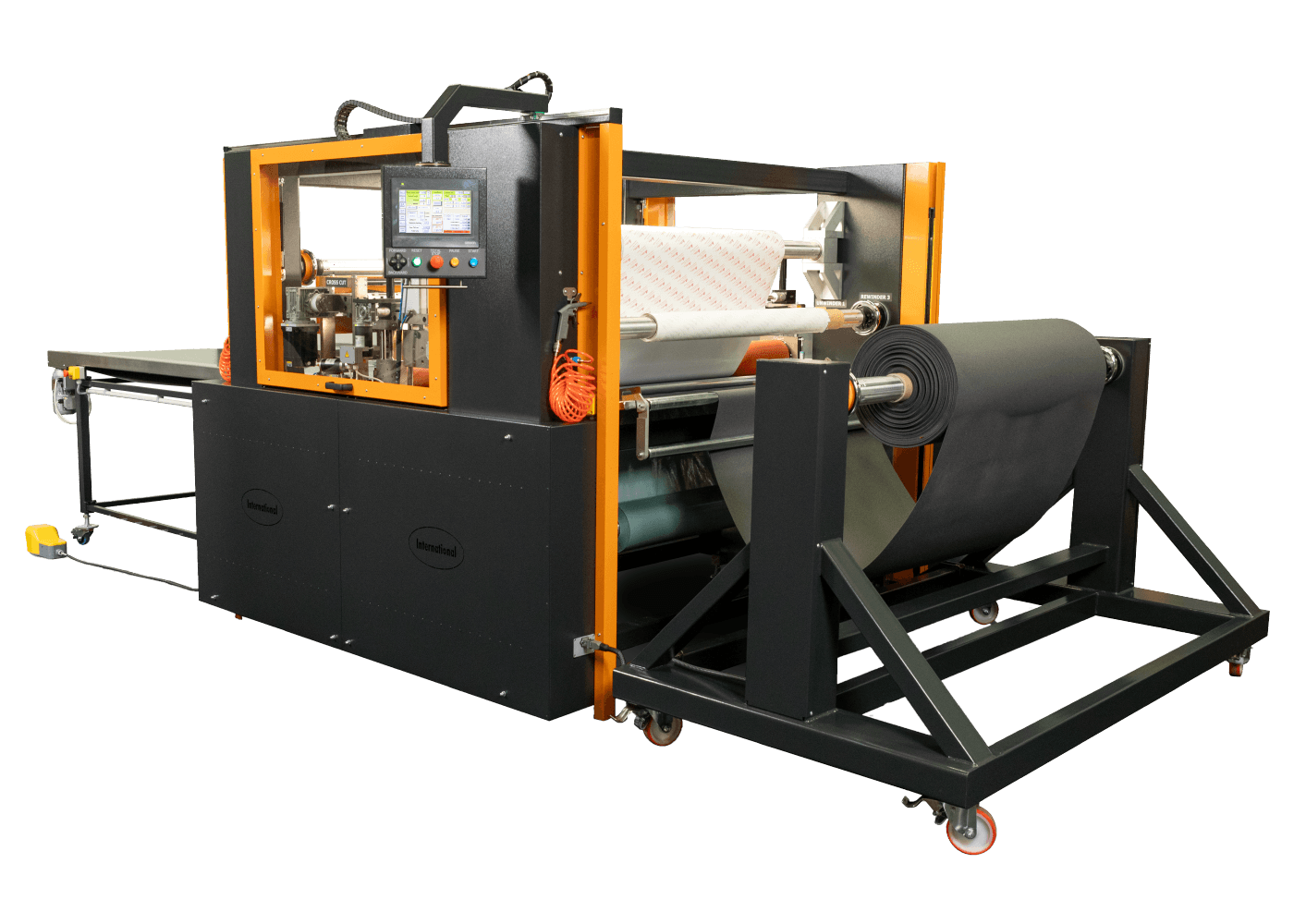

Slitters-Rewinders

The FEBA duplex and turret style slitting & rewinding systems are commonly used for converting self-adhesive & non-adhesive materials like carton sealing tapes (PVC, BOPP), paper tapes, medical & sport tapes, double-sided adhesive tapes, automotive & aerospace tapes, construction tapes, foam tapes, protection tapes, graphic & self-adhesive labels, laminated materials, textiles & non-wovens, flexible packaging and similar products.

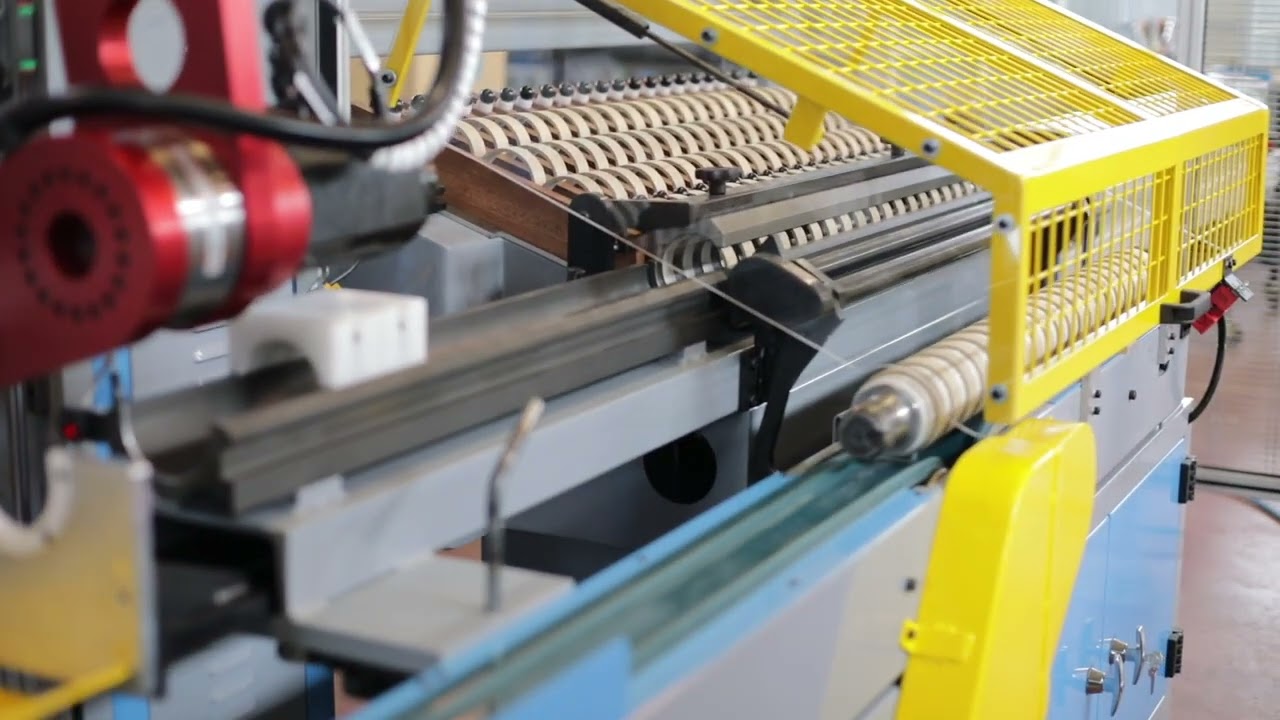

FEBA offers a variety of slitter rewinder designs & features to handle specific materials & processes: customized solutions to meet your unique requirements. Innovative systems for unwind tension and rewind torque control allows for minimal waste, and rolls of perfect quality for every type of material, with the production process controlled by a recipe driven system. FEBA slitting & rewinding machines can also include lamination & delamination stations, liner recovery rewinds, in-line perforating units, splicing tables, web inspection & web-break detection systems, in-line labeling, roll end tab (double sided adhesive), automatic roll unloading & core loading systems via robotics, and in-line or off-line packaging solutions.