Cutting-Edge Knife Tables

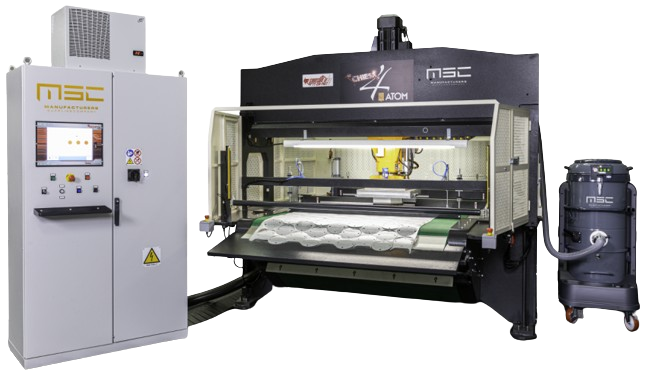

The Versatile Strength of the ATOM FlashCut Flex 2H 3026 B3

For the Automotive and Furniture Industries, timing and precision is absolutely necessary. When it comes to fabrics, leathers, foams, or any textile, the accuracy of your cuts and measurements will make or break your product quality. Thankfully, the solution is simple, versatile, and powerful. The ATOM FlashCut FLEX B Series is a collection of Dieless Knife Cutting Systems that provide turnkey solutions for design projects.

6 Key Points of Strength

- Robust

- Smartt

- Powerful

- Versatile

- Automatic

- Interactive

By combining rapid prototyping, seamless manufacturing, and a unique software package, the Flex B series streamlines the design process and yields consistent, accurate results. These systems are the premiere dieless cutting solution for a wide range of industries.

The most recent evolution of the FLEX series, the FlashCut Flex 2H 3026 B3 boasts several improvements in technology, software and structure. Its new compact design makes this machine extremely flexible, and capable of completing a wide range of industrial applications—making this machine the best solution for cutting leather and textile around.

Key Functionality of the Flex 2H 3026 B3

2H Configuration

The continuous cutting operation performed by the conveyor-bed offers maximum production. Two independent gantries, each equipped with a 5-Tool Cutting Head, ensures increased throughput & productivity—guaranteeing from 9 to 12 Full Hides per Hour. The material is fed onto the bed of the machine from the material handling device (material can be in roll or sheet form) into the cutting zone.

The 5-tool cutting head increases the overall versatility of the ATOM Flashcut B Series and can be equipped with the following features:

- Fixed, Electric Oscillation (EOK)

- Pneumatic Oscillating (PNEU)

- Powered Rotary Cutter (PRC)

- Powerful 11kW Vacuum Pump

- Unique Zoned Vacuum Table

- Independent Inverter Controlled Sectors

- Side Auxiliary Tools:

- Rotating Punches/Drilling Stations

- Kiss Cut Tool

- Creaser Wheel

- 45° Angle Knife

- Marking Pen

- 3rd Non-Rotating Punch Station

- Pricker Tool

Vision Plus 3026 B In-Line Hide Acquisition System

High Brightness Overhead Projection

The overhead projectors allow for a clear visualization of parts and commands for all materials run through the machine. This allows the cutting operation to be faster, more accurate, and less wasteful—fabricators enjoy the flexibility of these projectors because they allow easy cuts from any remnant or scrap, no matter how irregular the shape.

Scanning Module: Recognition & Interpretation Software

In addition to systems for pre-marked hides, the FlashCut scanning system automatically acquires the necessary data from the material you wish to cut. The analytic process reports provide precise and reliable information helping production management.

Through powerful nesting software, the FlashCut Flex 2H 3026 B3 system is capable of recognizing the outer leather contour, quality areas, potential flaws/defects, and reference points of any hide. This system uses an advanced algorithm for symbols recognition and interpretation, which, when paired with LED lighting from the projector and the closeness of the acquisition point to the material, ensures accuracy of cuts on any color hide, in any light environment.

Conveyor System with Independent Take-Off Table

The basic structure of the FlashCut Flex 2H 3026 B3 boasts two independently working areas. After the materials have been cut on one half of the table, they are automatically indexed to the take-off table. The operator can then (by means of the foot control bar) index the cut pieces forward to the nominal working position and collect them comfortably and quickly. The operator can strip the cut parts while the machine automatically reloads the material and the cutting process continues, proving unbeatable performance and continuous production.

Producing High Productivity: The FlashCut Flex at Work

From its key strengths to its functionality, it’s clear: this machine is a game changer for the any industry that requires precise, accurate materials for production. If you still aren’t convinced, check out these machines at work.

Manufacturers Supply Company is a proud provider of the ATOM FlashCut Flex 2H 3026 B3. This machine will be on order for our customers soon, and we will be hosting a Leather Cutting Technologies Open House at our facility near the middle to end of July 2017. This is a unique opportunity to see this machine in person, and to learn about all of the cutting solutions that will benefit your company and improve your manufacturing process. Please contact us for more details about this event.