Precision Surfaces: Cutting Edge Solutions

Cutting Pads & Boards

Rochling Hydroma & Manufacturers Supplies Company have been a reliable partner for the manufacture & supply of pure polypropylene cutting pads & boards for cutting soft & semi-rigid materials for many decades. Whenever the cutting of synthetic materials is involved, Rochling Hydroma & MSC are present – be it as an initial equipment provider for die cutting machines or with the users for replacement demands.

Advantages of

HYDROMA® QUALITY CUTTING BOARDS

Optimum Cutting Results

In the material selection and manufacturing processes, Rochling Hydroma inserts their special knowledge into the products, the objective being an optimum cutting result, maximum accuracy and long service life of both the cutting pad & cutting tool. The surfaces of Hydroma® cutting pads & boards are smooth on both sides, bright-pressed or planed as standard, or roughened on one side for bonding a plywood block base or similar substrate.

Fields of Application

Hydroma® Cutting Boards are perfectly suitable cutting pads for all types of cutting machines, cutting processes and cutting tools:

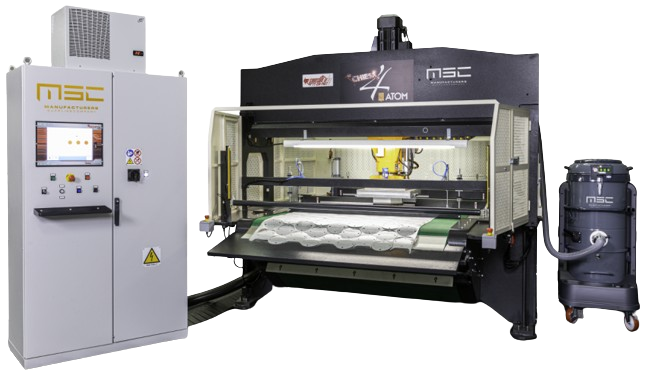

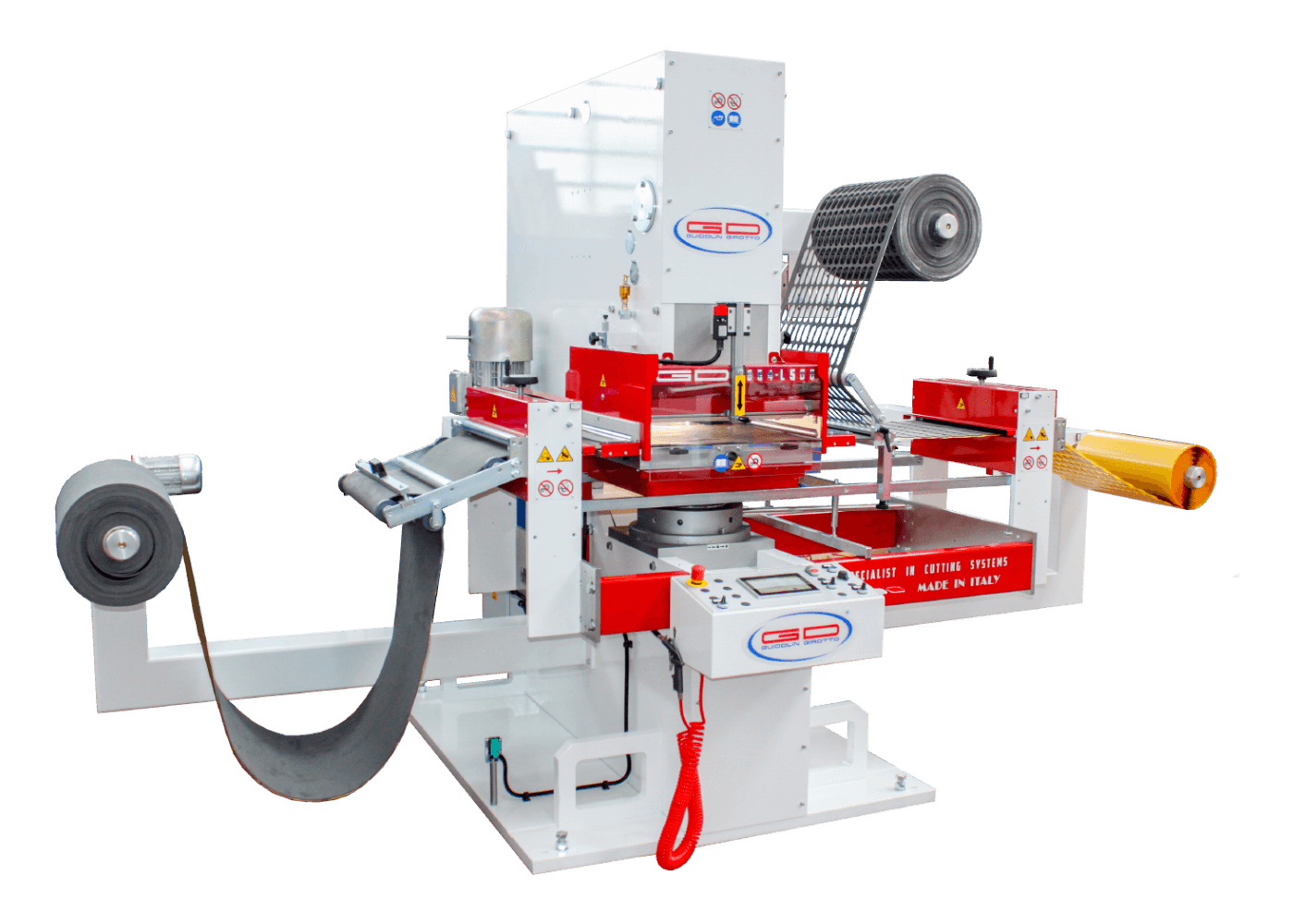

- Swing-Beam Clicker Presses

- Hydraulic Up-Stroke Platen Presses

- Traveling Head Die Cutting Presses

- Full Beam Cutting Presses

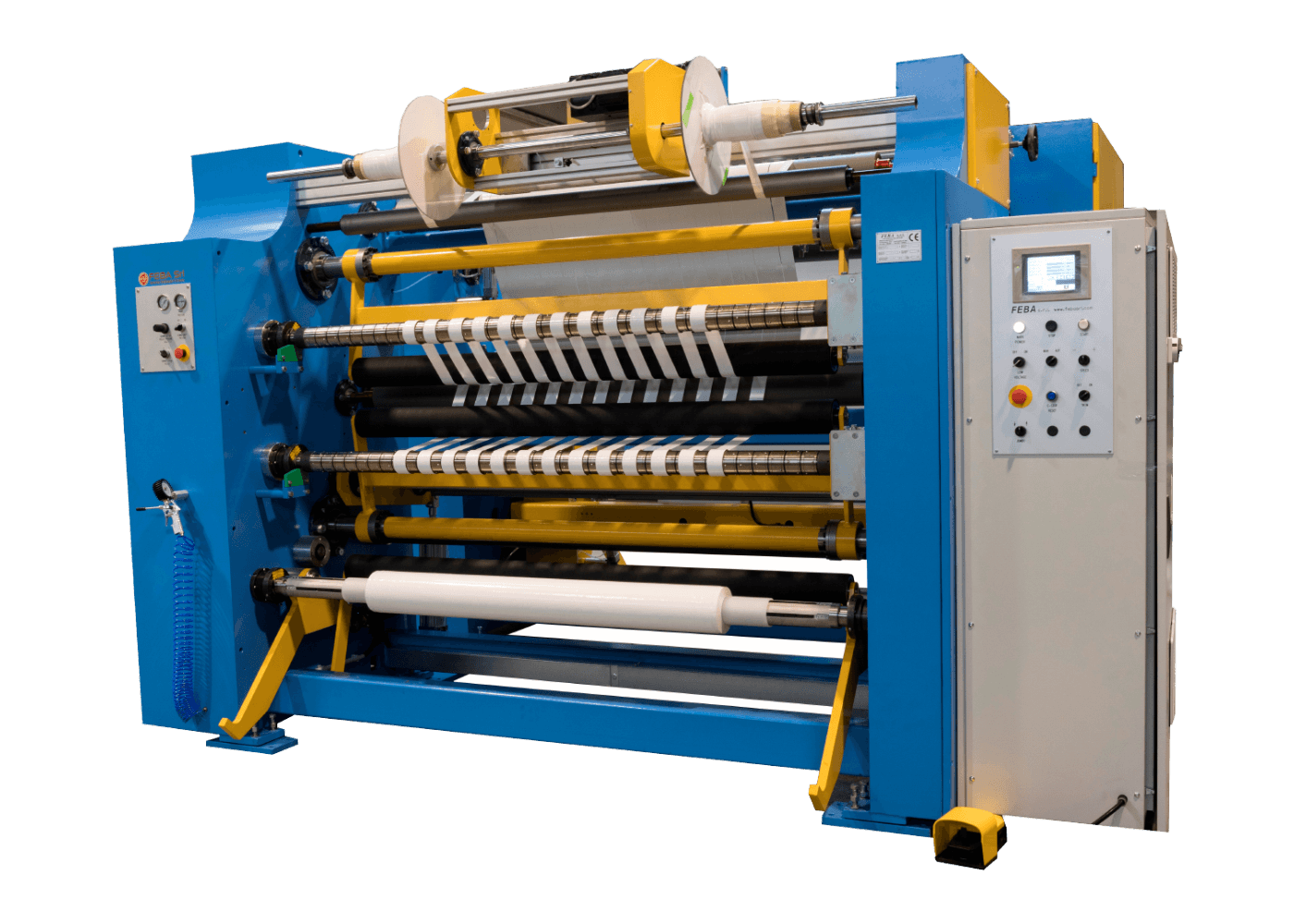

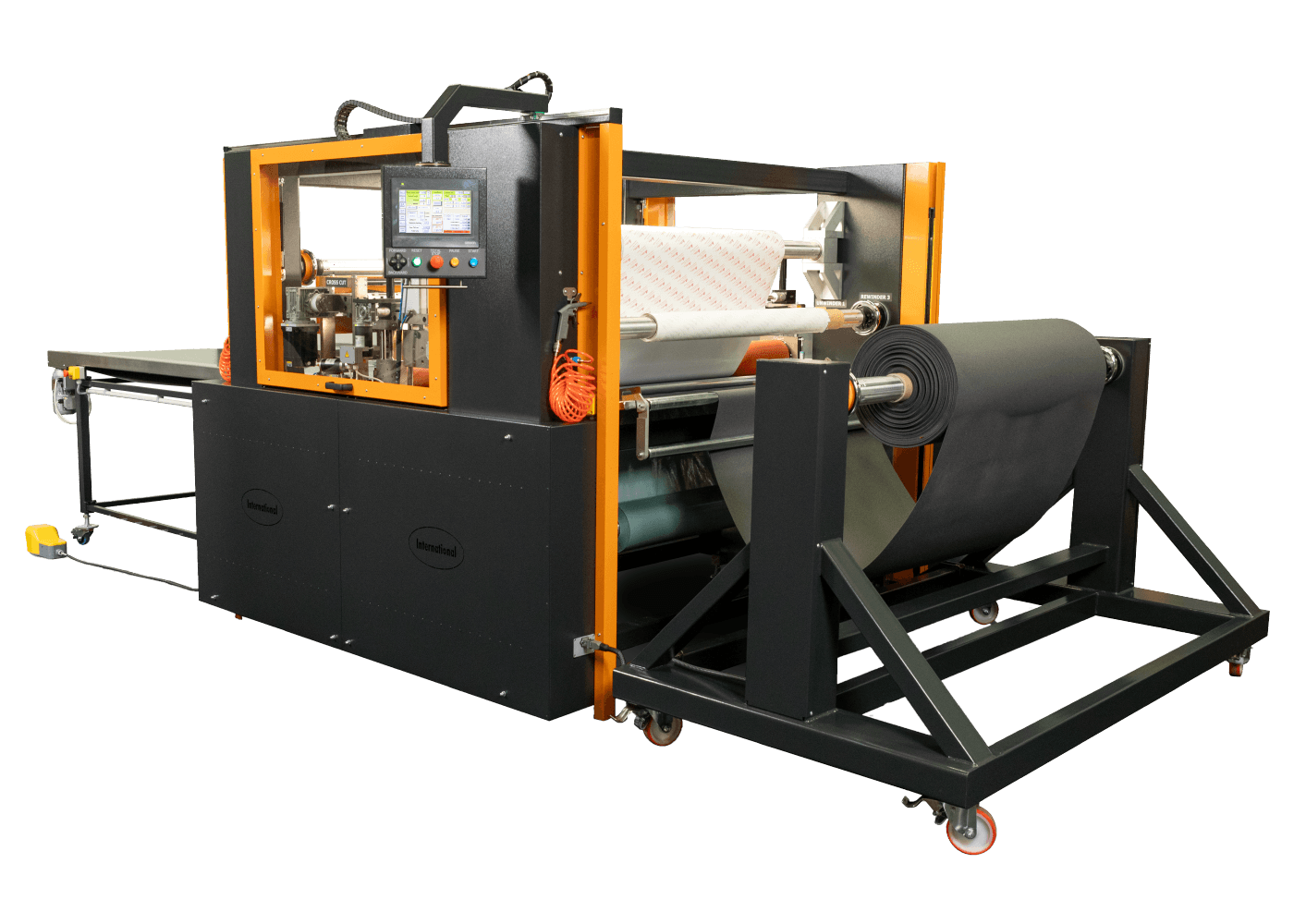

- Roller Presses & Rotary Die Cutting Machines

- Oscillating Knife Cutting Tables & Systems

Hydroma® Cutting Boards can be used on both sides and are suitable for cutting all types of soft & semi-rigid materials including:

- Leather and insole materials

- Gaskets in their various forms

- Foam and rubber

- Industrial fabrics & technical textiles

- Composite materials

- Adhesives and laminated materials

- Thermo-plastic materials

- Paper, corrugated & printed materials

Benefits of Cast Cutting Pads & Boards

- High quality cutting surface to decrease tool wear, increase pad wear and deliver cleaner cuts.

- Manufacturing process involves longer cycle times of heating & cooling the PP material.

- Higher degree of parallelism tolerance and significantly reduce tension which eliminates the bowing effect commonly seen with extruded plastic pads.

- Cast polypropylene cutting boards are specifically designed for die cutting applications and are proven to provide better cutting quality, increased pad wear, better tooling wear which equates to less defective parts & increased production.

Stock Product Range:

HYDROMA® QUALITY CUTTING BOARDS

HY84 Perlamon

-

Uses:

Universal, especially for more rigid materials -

Cutting Materials:

Textile synthetics, composites, plastics etc.

HY78 Natural

-

Uses:

Cutting board for universal usage -

Cutting Materials:

Textiles, felts, fleece, gaskets, foam, foam plastics, rubber etc.

HY72 Red-Brown

-

Uses:

Shoe & leather industry -

Cutting Materials:

Leather & soft materials

Others

Extend the Life of your Hydroma® Quality Cutting Pads & Boards

- Store boards horizontally to prevent warping

- Avoid cutting in only one area of the pad – utilize as much of the pad as possible

- Rotate and flip the pad periodically for even wear

- Sharpen your cutting tools to minimize cutting depth (0.3mm recommended)

Additional Services Available from MSC

- Custom Dimension Cutting: Cut to the exact dimension to fit your die cutting press.

- Edge Surface Grooving or Boring: For rail or special surface mounting applications

- Cutting Pad Assembly: Rough back surface mounting to birch wood with tape or glue.

Downloads

View Hydroma Cutting Surfaces Data Sheet

PDF - 121 KB

View Hydroma Cutting pads Data Sheet

PDF - 298 KB