Latest Updates & Insights

Blog & News

Uncategorized

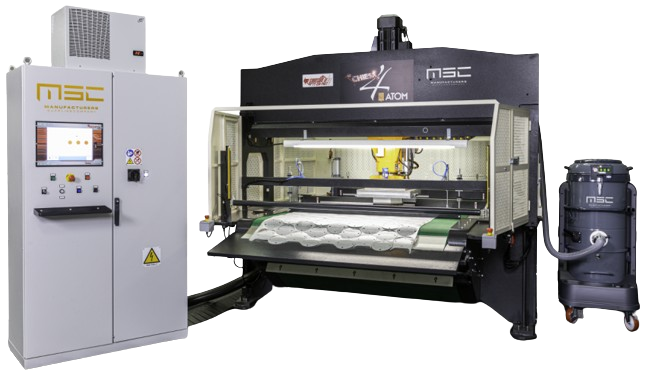

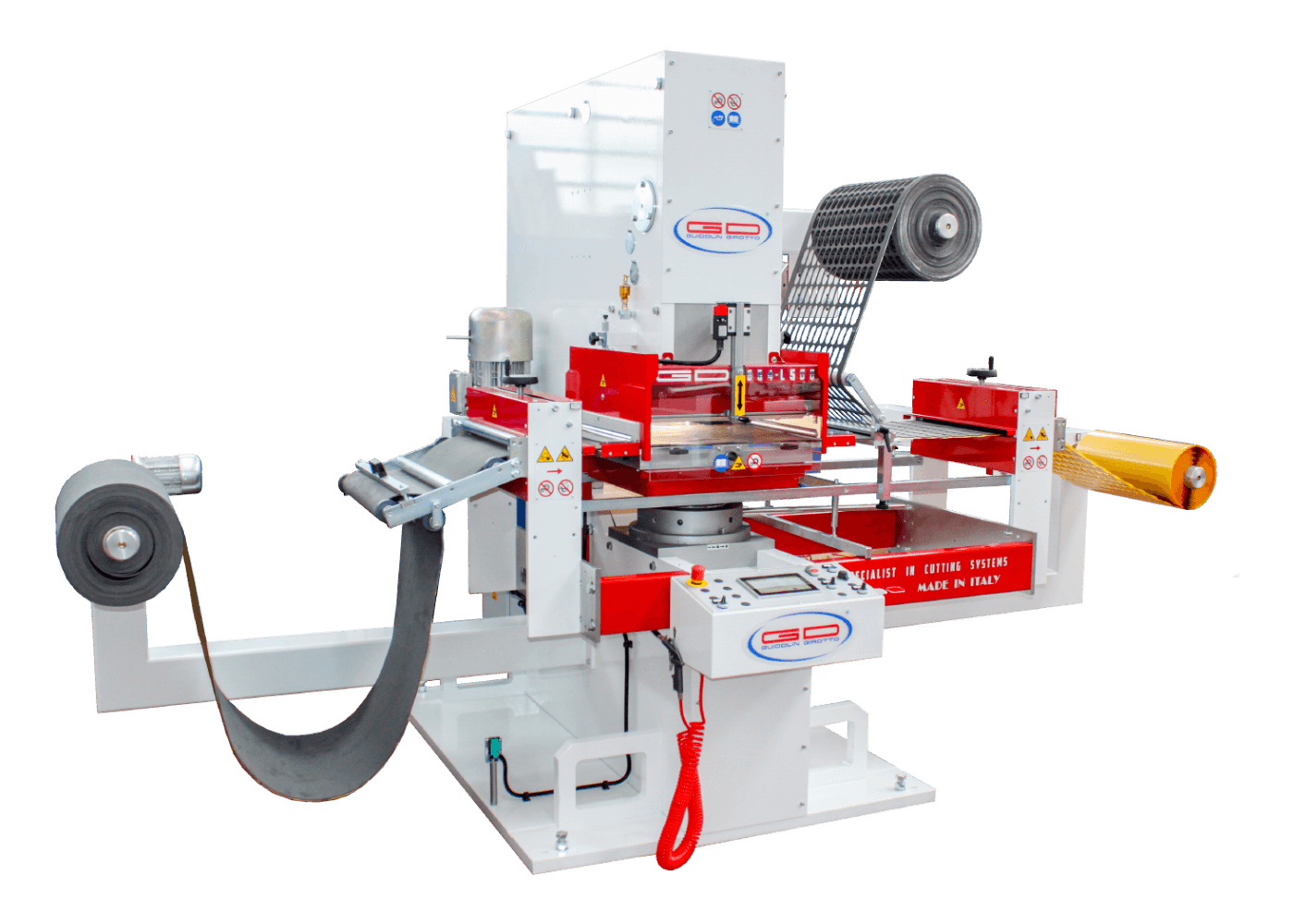

SWING ARM CLICKER PRESS MAINTENANCE

The most widely used die cutting machine in the world:

mfgsup-admin

January 19, 2024

Uncategorized

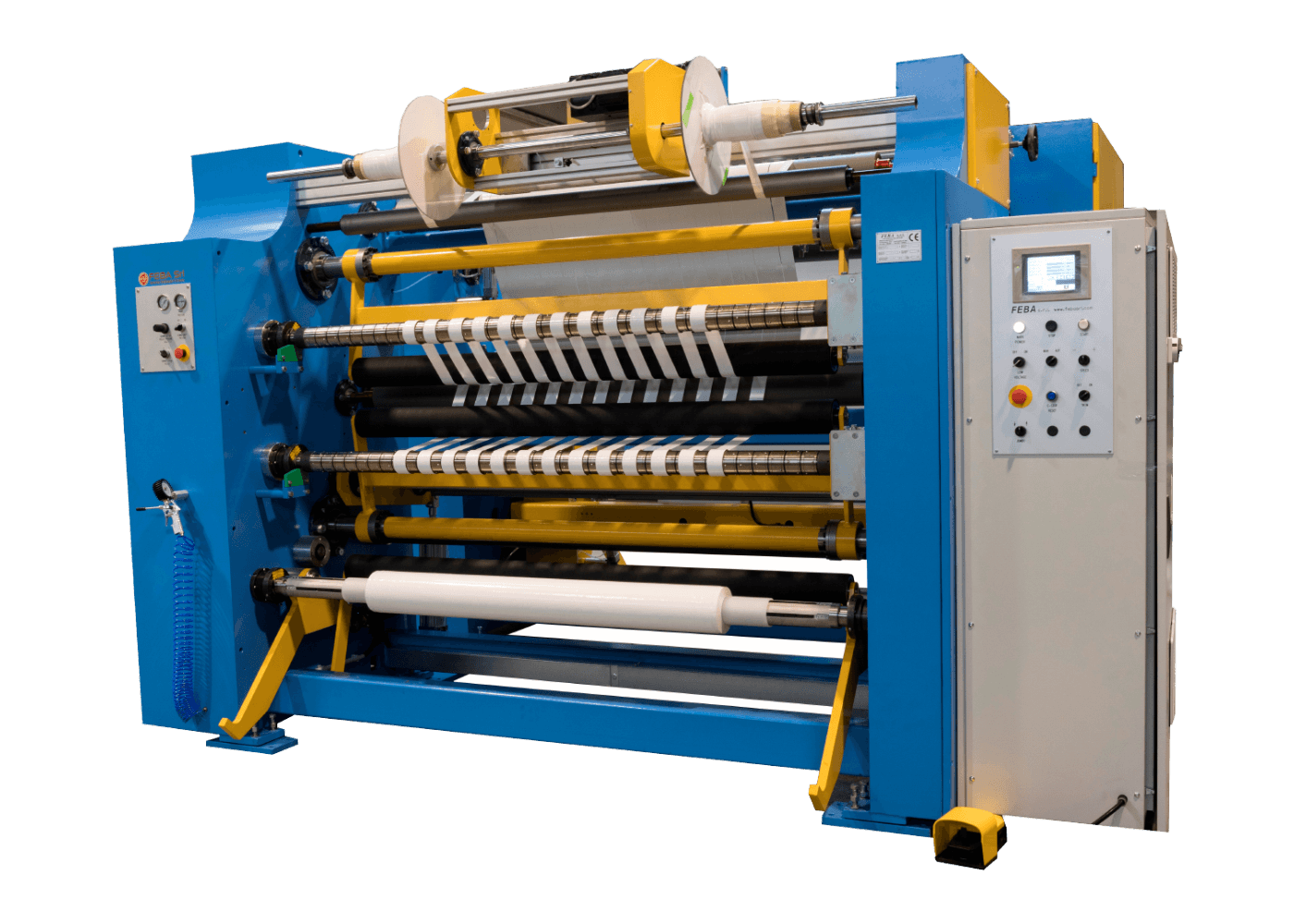

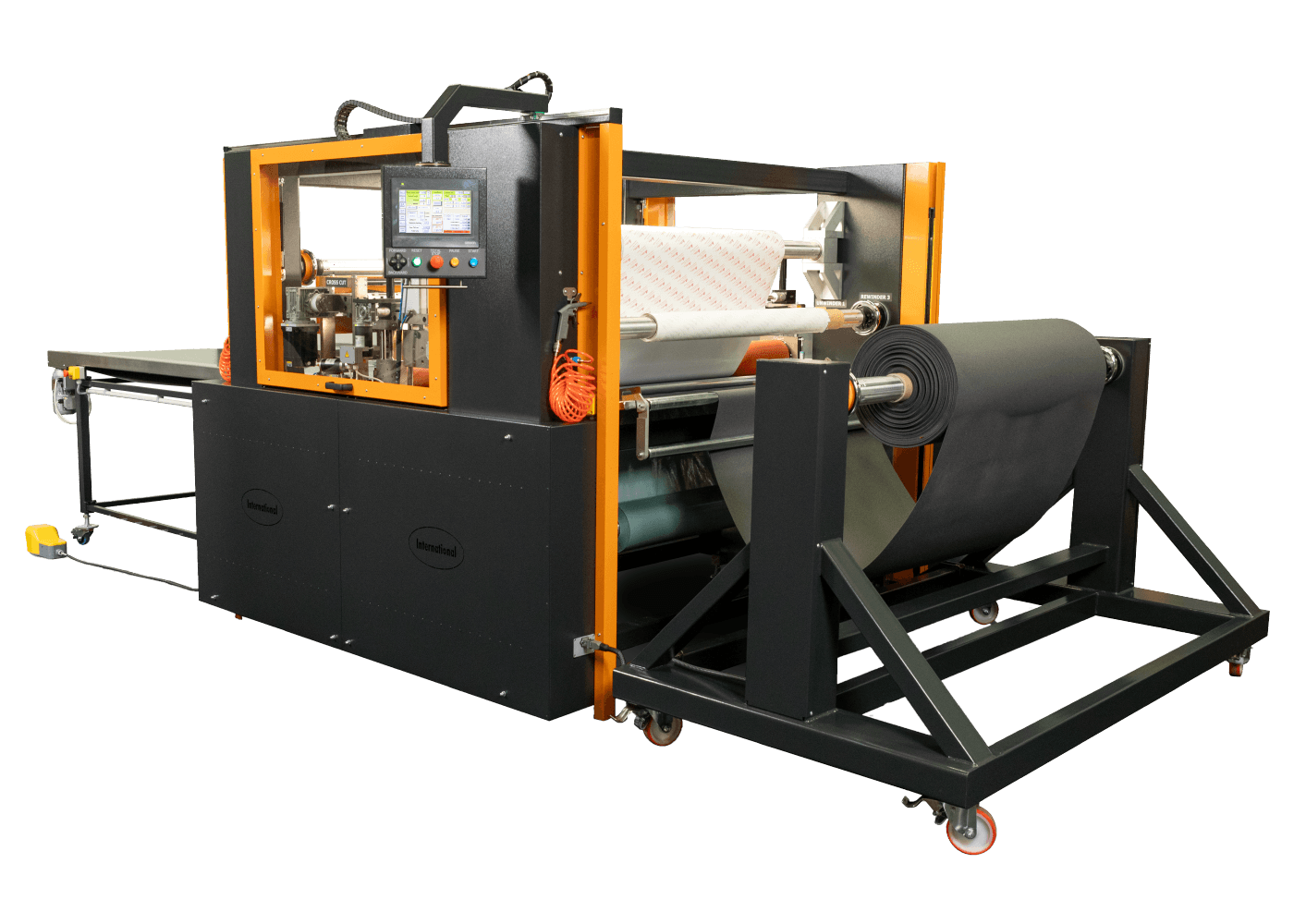

BEST METHODS FOR BULK GASKET PRODUCTION

Finding the best method for producing quality gaskets is an

mfgsup-admin

January 20, 2019